Planning for future clean energy skills in the East Midlands

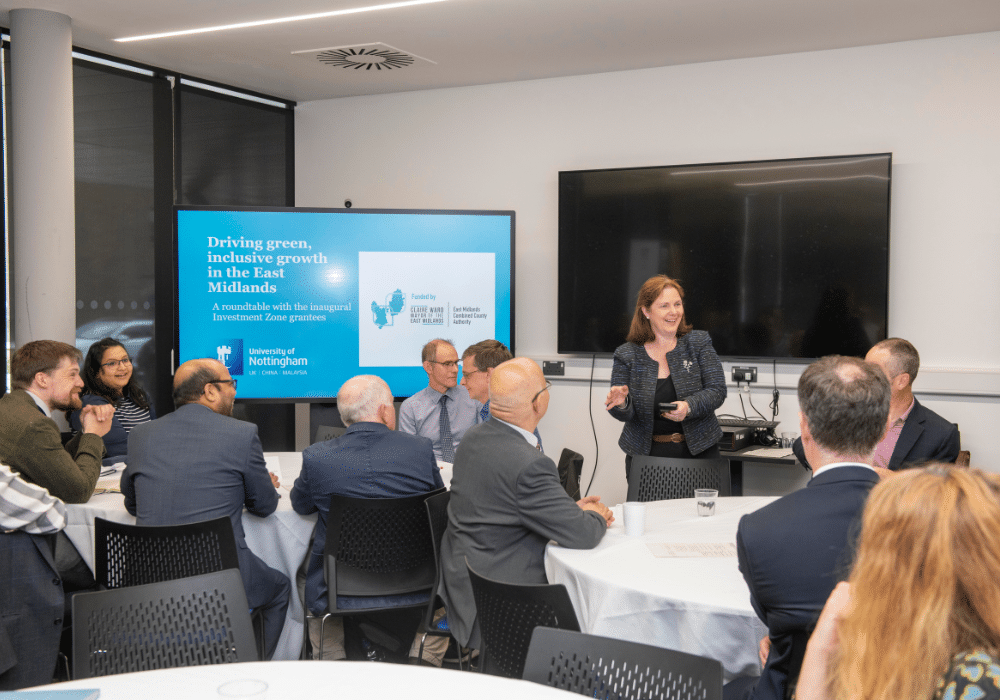

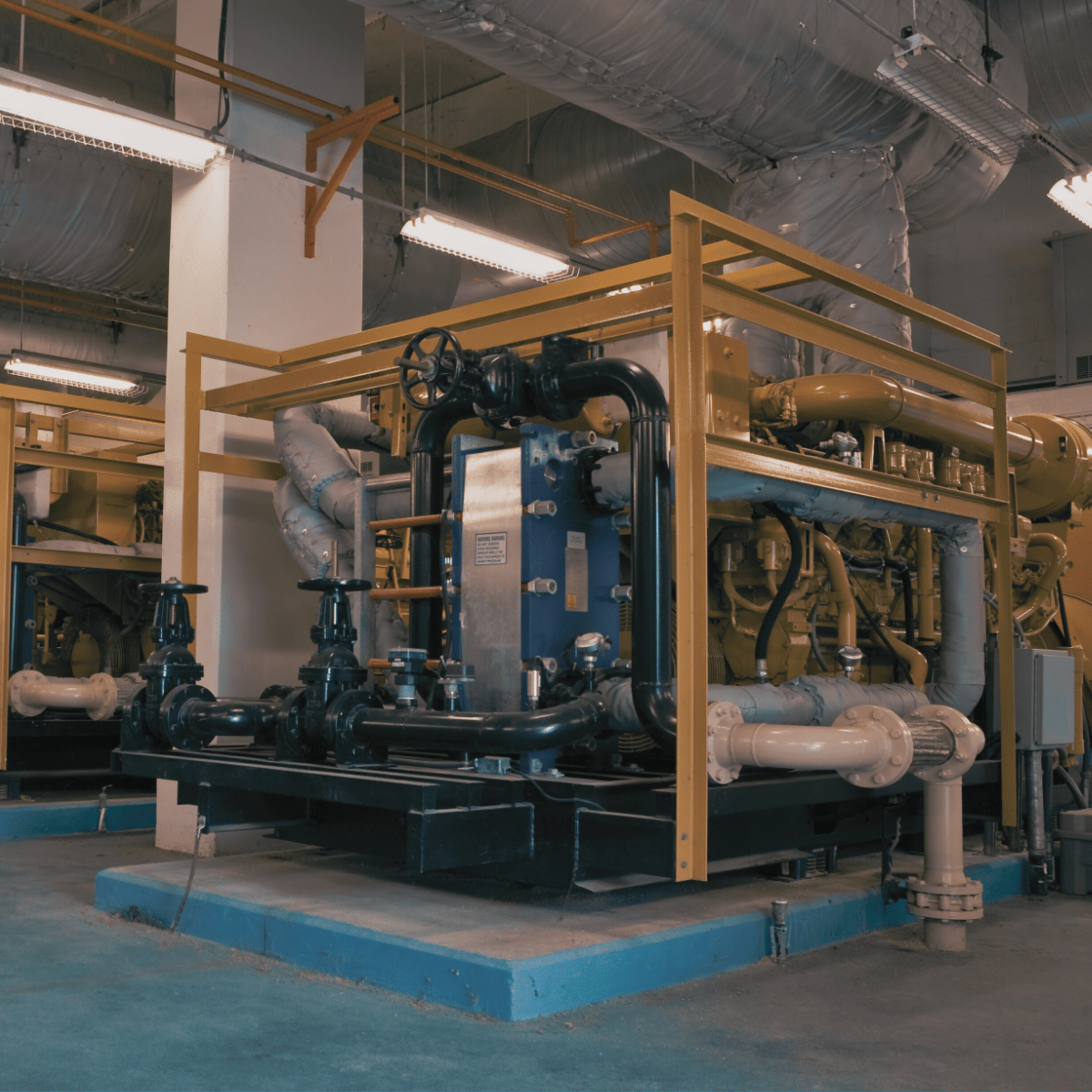

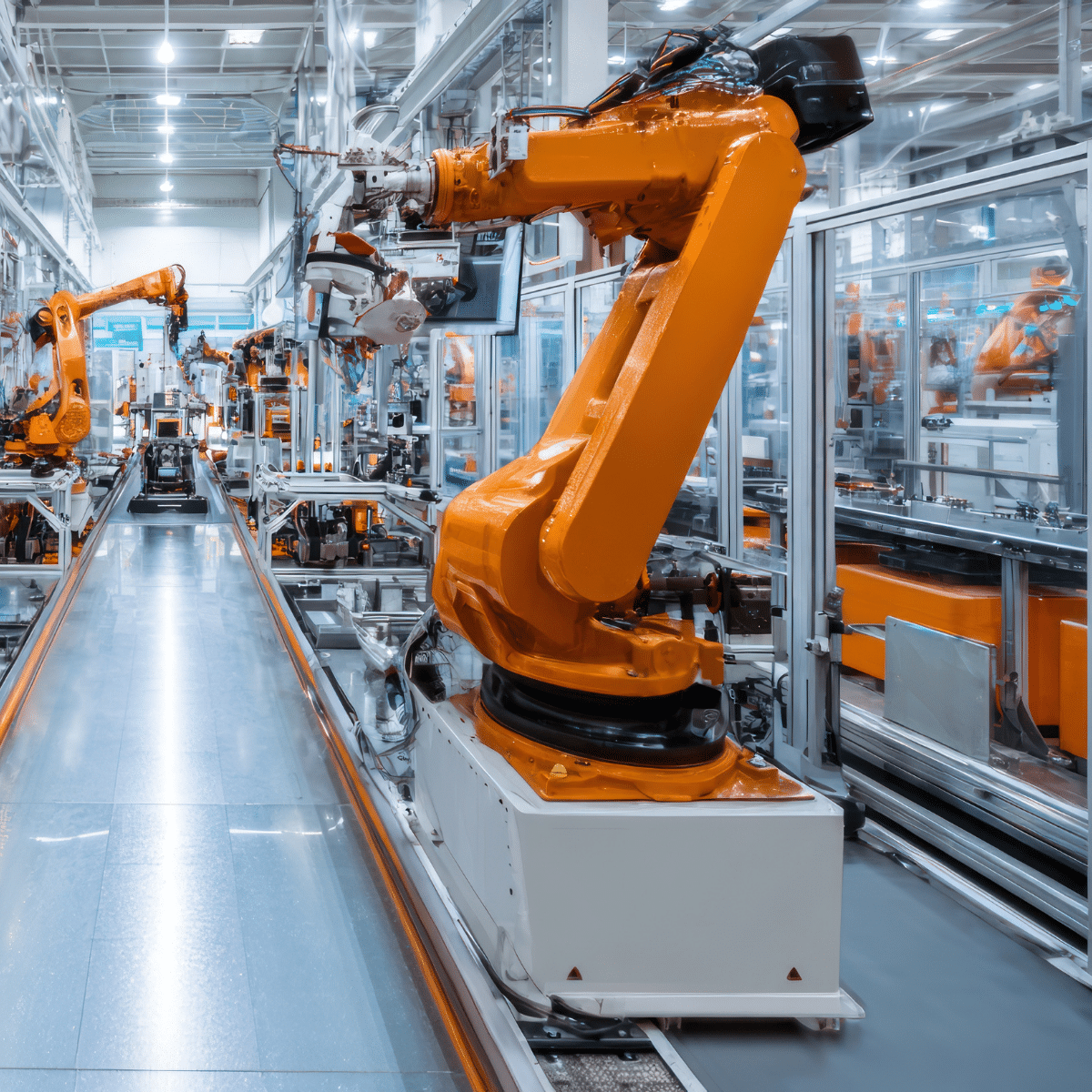

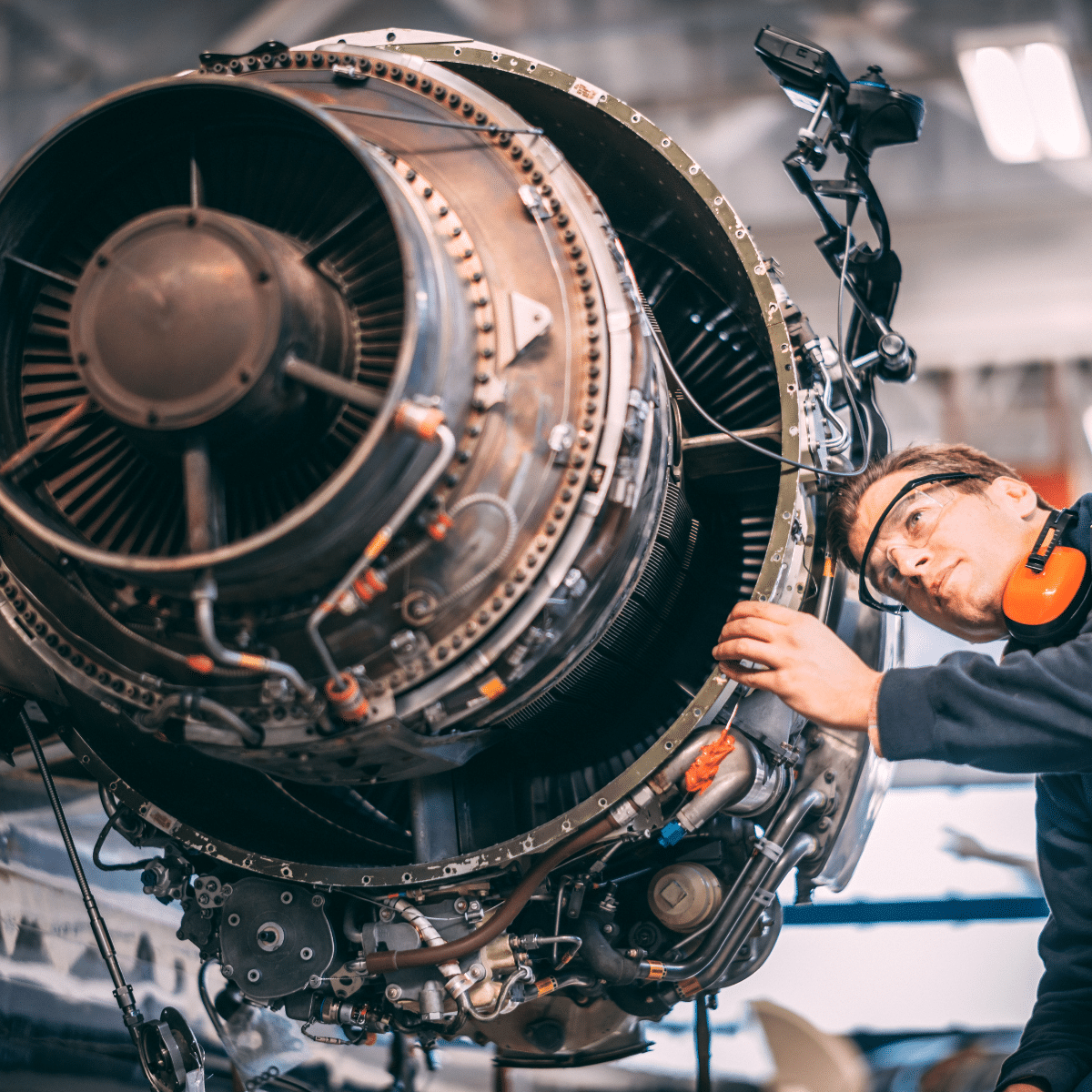

To support the growth of the clean energy and advanced manufacturing sectors, this project mapped the current skills in the region, identified future needs, and created a clear plan to guide investment in skills and training. University of Derby led this project with support from Nottingham Trent University, Nottingham College, Chesterfield College, Make UK, and Derbyshire County Council.